Descripción

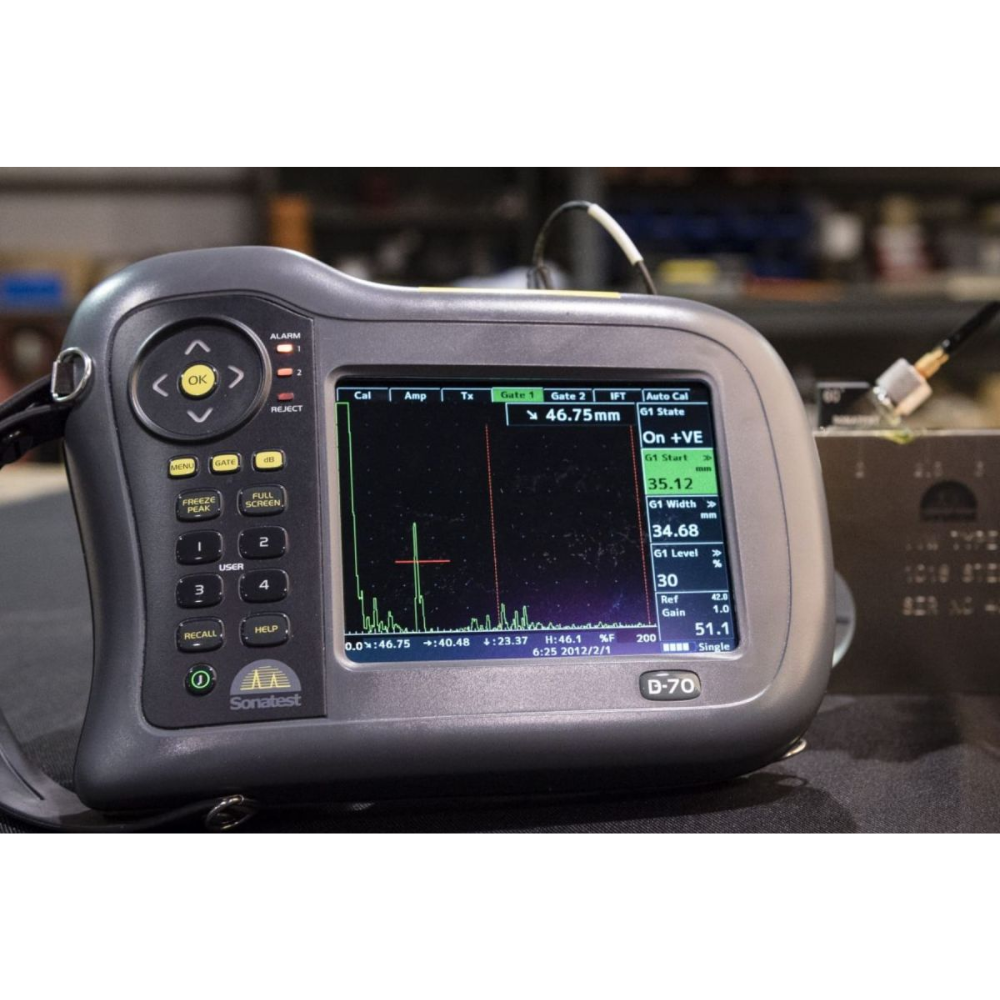

El Masterscan D-70 ofrece al inspector un conjunto de herramientas y software totalmente capaz y funcional para la inspección en todas las aplicaciones. Entre sus funciones se incluyen el B-Scan codificado, el registro avanzado de espesores y la capacidad Dryscan en una carcasa portátil.

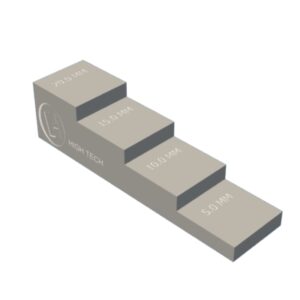

Se pueden añadir funciones y realizar actualizaciones en el entorno de trabajo, lo que reduce el tiempo de inactividad y aumenta la flexibilidad de trabajo. Los altos niveles de resolución cerca de la superficie, la potencia de penetración (450 V pulser – cuadrado y pico) y la excelente relación señal/ruido son funciones clave en la gama Masterscan.

Las aplicaciones típicas son la fabricación de soldaduras, la detección de la corrosión, la inspección de materiales compuestos, los ensayos de adherencia, las piezas forjadas y fundidas, la generación de energía (incluido EMATS) y la inspección UT general.

Reliable, Rugged & Robust

An instrument’s ability to perform in harsh environments with proven reliability is an important aspect of flaw detector ownership and this is enhanced by the Masterscan’s outstanding battery performance which is up to 10.5 hours from full charge. The Masterscan’s enclosure is constructed using automotive grade impact resistant materials, offering excellent water resistance. Explosive Testing MIL810-G standards have been passed, together with environmental testing which has confirmed the instrument fully functioning at temperatures above 55ºC. The Masterscan D-70 has a colour transflective VGA display and maximum readability is achieved through adjustable brightness and the choice of 9 colour palettes, including black-on-white LCD emulation mode.

Advanced Defect Sizing Tools as Standard

Weld and pipe inspection are major applications for the Masterscan D-70 and they are equipped with the latest software tools for defect sizing. The use of integrated sizing software reduces analysis time and speeds inspection. Multiple standard sizing techniques are essential for service companies working to different customer standards, especially as service work becomes more international and operators are required to work to different codes.

Sizing Techniques and Software Options include:

- DAC (Standard)

- Split DAC & DGS/AVG (Option)

- TCG (Option)

- Backwall Echo Attenuation (BEA) Option (requires TCG)

- AWS (Option)

- AVG/DGS (Option)

- API (Option)

- Interface Trigger (Option)

- Corrosion Software (Option)

- Dryscan Function (Option)

UT-Lity Data Management Software

UT-Lity software provides everything you need to manage your inspection data. The standard version is FREE with every instrument and gives you the ability to view, move and manage Calibrations, A-Scans, B-Scans and Thickness Logs both on the instrument and on your PC. With UT-Lity you can also create customised inspection report templates, cut-n-paste information to other applications and create printable pdf documents.

- Load, store, manage files both on the PC and on a connected flaw detector

- Save, analyse, colour code and export thickness logging data to spreadsheets/asset management software

- Update the Flaw Detector and Firmware as and when updates become available on our website

Valoraciones

No hay valoraciones aún.