Description

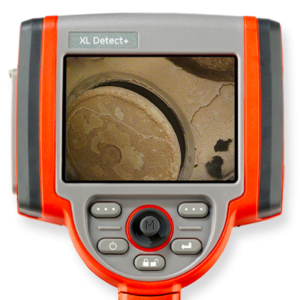

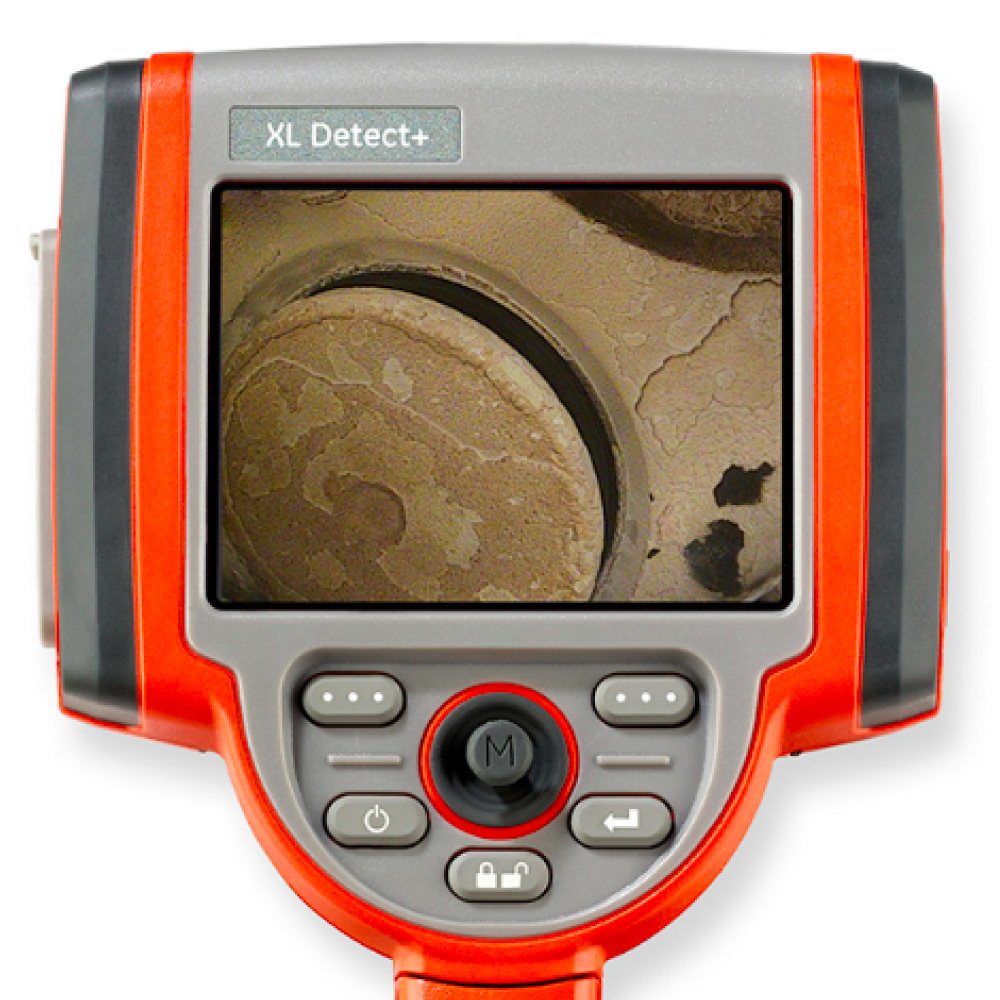

Introducing the new XL Detect weld video probe.

Perform asset inspections with confidence thanks to the reliability of a 4-hour battery life and the efficiency of its user-friendly ergonomic design. With Menu Directed Inspection (MDI) 2.0, an intuitive software program that guides users through the inspection process to automatically label images and organize results, the XL Detect and XL Detect+ VideoProbe systems offer optimal protection to help reduce operating costs, improve probability of detection and increase ROI.

Quality begins in the process of building the purity pipelines used in pharmaceutical production facilities. Whether off-site at a skid manufacturer’s facility or in the on-site construction of interconnecting piping, the integrity of the identification of each and every weld must be verified by high-quality imaging to ensure regulatory compliance prior to use. Designed for high purity weld inspections, the XL Detect+ Weld videosonde helps detect surface defects in welds and high purity pipe construction with clarity, ease and accuracy.

It features a specially designed probe with a flexible flex section that allows easy navigation around 90-degree bends, which helps reduce wear and tear on the device while increasing inspection efficiency. A new larger, brighter LCD display offers best-in-class image quality, improved inspection productivity and increased probability of detection.

Features:

Ultra-sharp image quality:

Complete inspections with unmatched image clarity with an 85% larger and 3x brighter display (3.7″ and 5″ options). Advanced optics and powerful light output mean less eyestrain during long inspections and more accurate images. Because when you can see clearly, you increase the probability of detection, speed up your inspection workflow and deliver results with confidence.

Ruggedness redefined:

Built to withstand the rigors of the industrial workplace, the XL Detect and XL Detect+ strategically incorporate shock-absorbing materials and gaskets to resist impact damage and prevent dust and water intrusion. Tested to IP64 (IP55 for the XL Detect), MIL-STD-810G and MIL-STD-461F, reduce your maintenance costs with military-grade durability you can rely on, even in the harshest environmental conditions such as drops, 1.2 m (4 ft.), driving rain and freezing rain, vibration, high humidity, dust, salt spray and explosive atmospheres.

Automated inspection reports with MDI:

Intuitive Menu Driven Inspection (MDI) 2.0 guides users through the inspection process to automatically label images and organize results. Click to report at the end of an inspection to save time, improve quality and streamline the decision-making process.

On the fly to flexibility:

Whether you’re climbing a 100-meter tower to inspect a wind turbine gearbox, crawling over a refinery heat exchanger or crawling under a turbofan engine on a test stand, it’s all about the details. Lightweight and easy to use, the XL Detect is equipped to tackle whatever comes its way, with the portability to move from one inspection area to another.

Reviews

There are no reviews yet.