Description

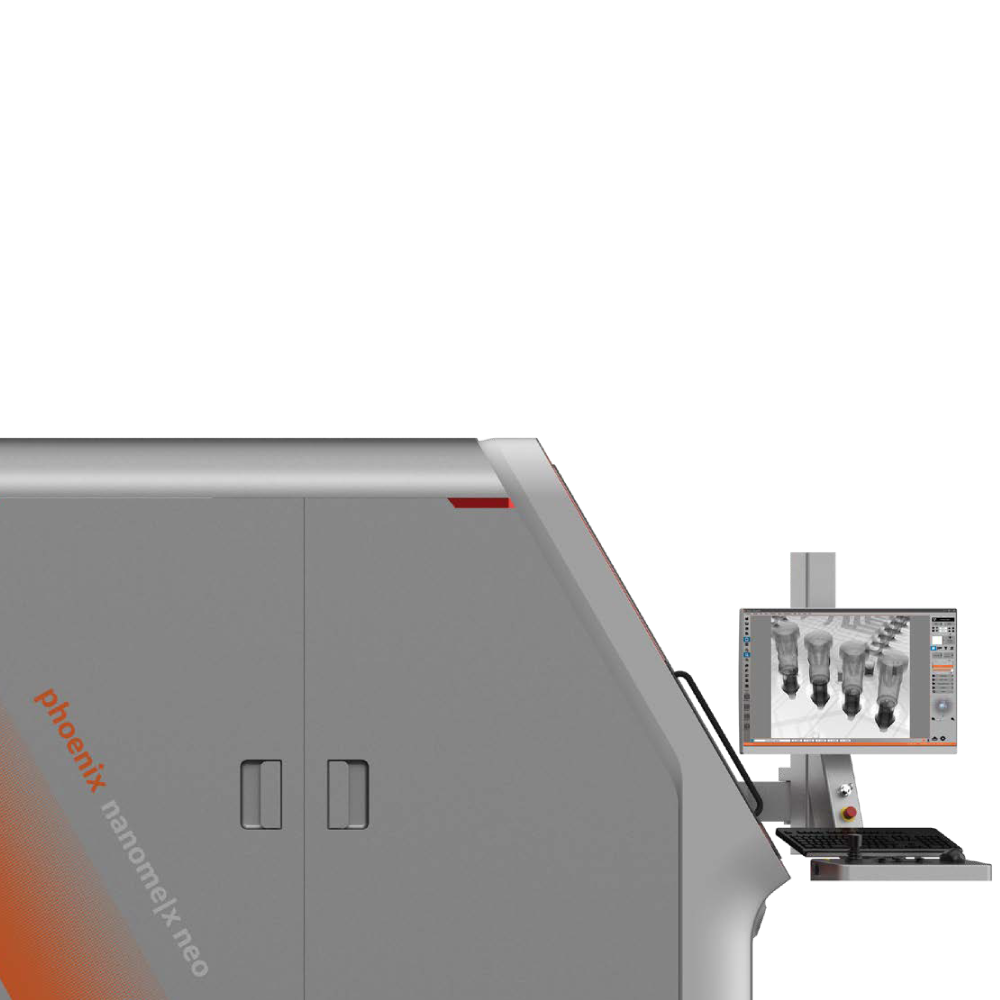

With innovative engineering coupled with ultra-high positioning accuracy, Phoenix Microme|x Neo and Nanome|x Neo are ideal for industrial X-ray electronics inspection in process and quality control for increased productivity, failure analysis for increased safety and quality of your products, and R&D where innovations are born. Both enable automated X-ray inspection (AXI) of electronic components (such as semiconductors, PCBs, electronic assemblies, sensors and lithium-ion batteries) in the industrial, automotive, aviation and consumer electronics industries.

Nondestructive electronic inspection starts here

Innovative and unique features and extreme high CT positioning accuracy make both the Phoenix MicromeIx 160 and 180 neo and the NanomeIx 180 neo the effective and reliable solution for a wide spectrum of 2D and 3D offline inspection tasks: R&D, failure analysis, process and quality control. .

The Phoenix|x-ray X|act inspection software offers easy-to-program CAD-based µAXI, ensuring automated inspection in the micrometer range. Another unique benefit is Waygate Technologies’ numerous flat-panel detector options, from the highly dynamic DXR 250RT with active cooling to the large DXR S100 Pro with brilliant resolution. There is always an imaging string that perfectly matches your particular application.

Benefits

- Brilliant live inspection images thanks to Waygate Technologies’ highly dynamic DXR digital detector array

Unique 180 kV / 20 W high power micro- or nano-focusing tube for even high absorption electronic samples

Minimized setup time thanks to highly efficient automated CAD programming

Live overlay of CAD and inspection results even in rotated oblique inspection views

Extremely high defect coverage and repeatability

Unique features

- New detectors with higher pixel resolution (85/100 µm) are more competent for the inspection of semiconductors and small electronic components.

- Ease of use: inspection report will be generated automatically after inspection

- X|act package for CAD-based µAXI automatic programming and inspection

- Diamond|window for up to 2 times faster data acquisition with the same level of image quality

- Optional 3D CT scans in 10 seconds Shadow|target to avoid radiation damage to sensitive devices by reducing unnecessary doses

- Optical and X-ray navigation map for fast positioning and easy programming

- Patented OVHM technology enables synchronized motion and ergonomic setup for easy viewing configuration.

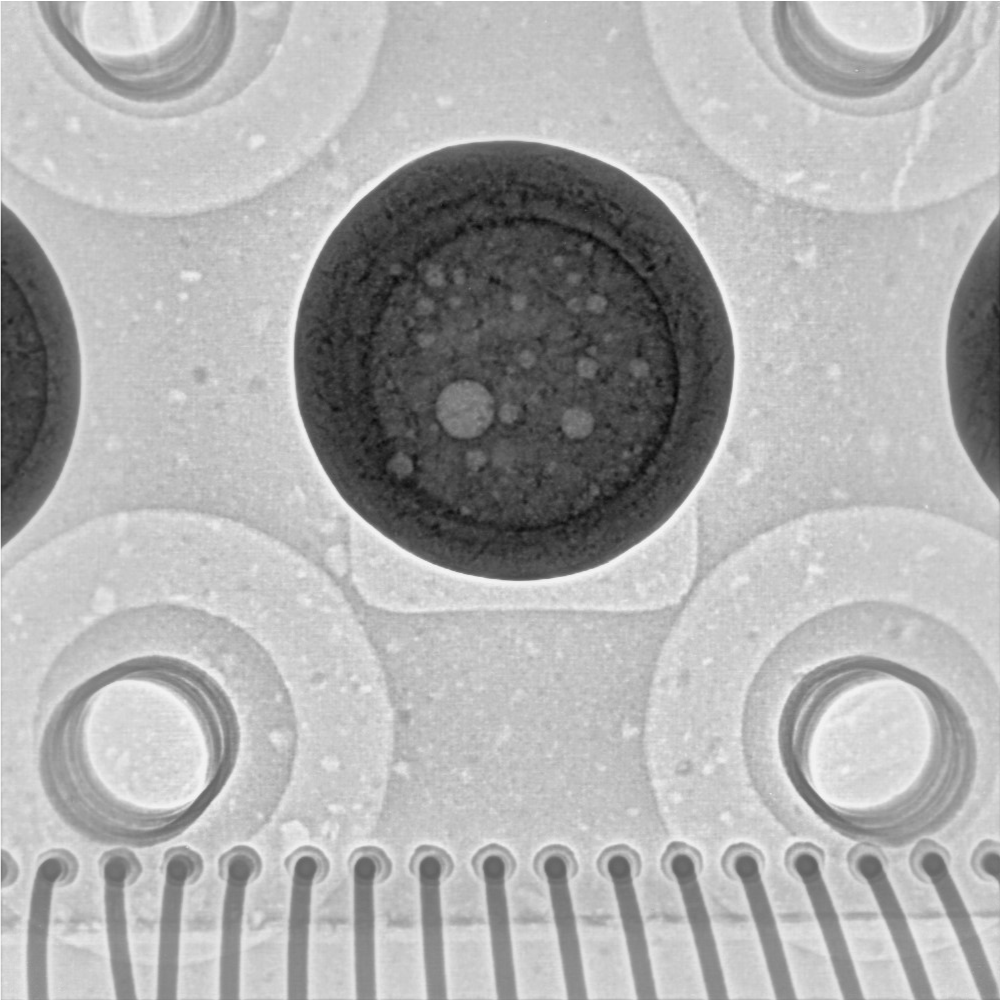

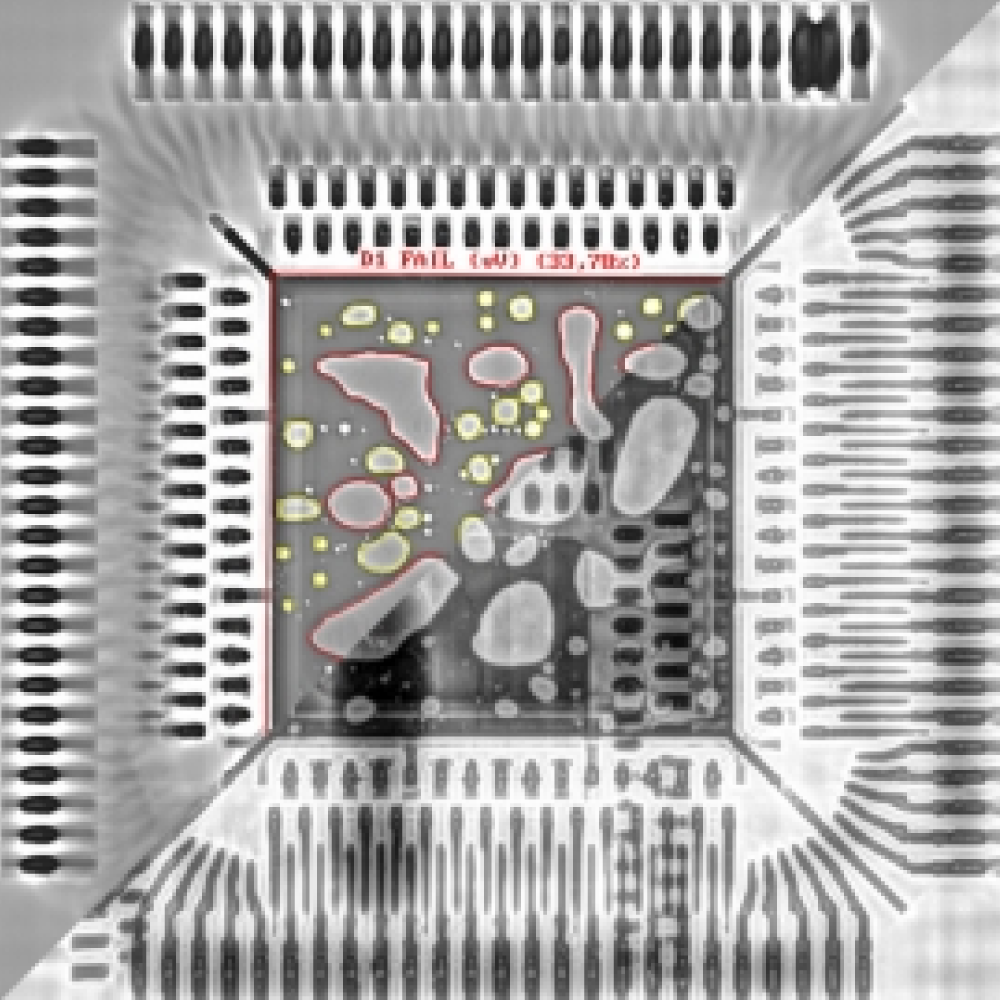

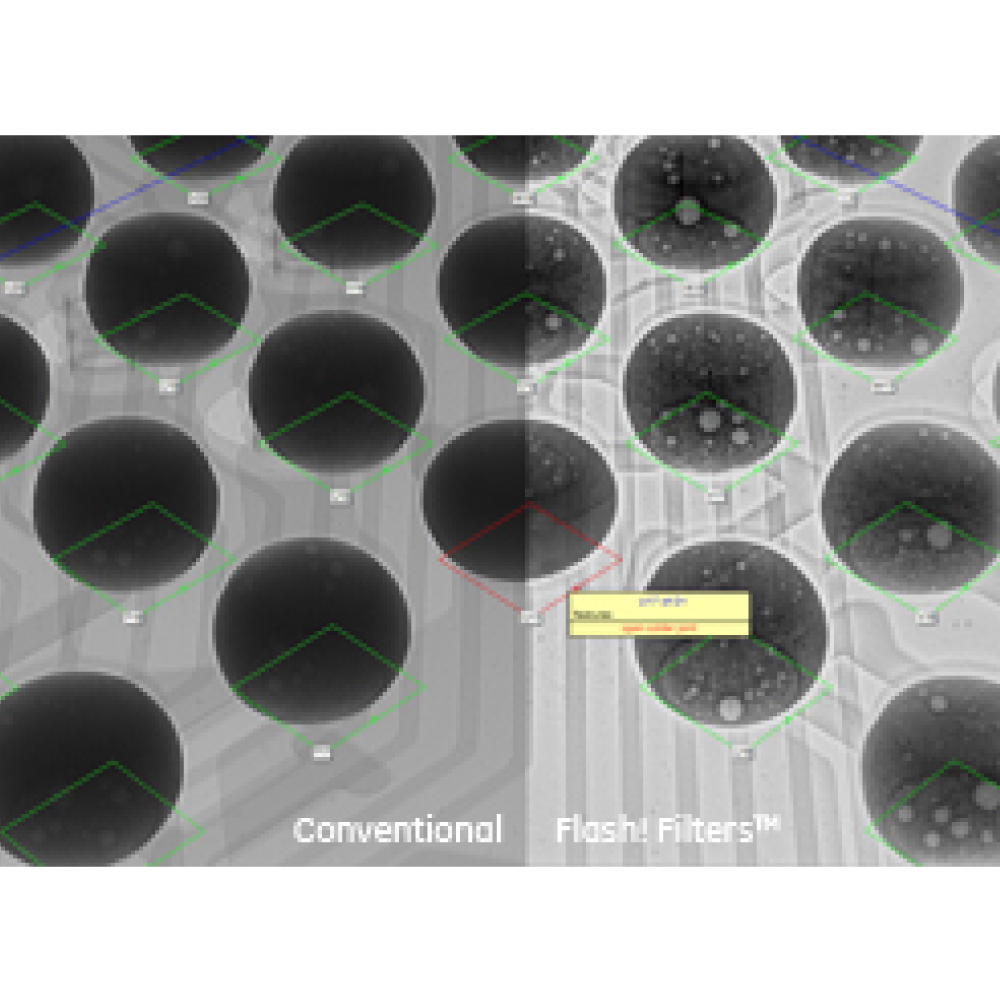

- Flash!Electronics™, Waygate Technolgies’ best-in-class image processing technology, specially optimized for electronic inspection.

- Dose|manager combined with Shadow|target to prevent radiation damage to sensitive devices by reducing unnecessary doses

Applications

- Battery inspection

- Quality assembly such as BGA, wire sweep, PTH or QFN/QFP

- Other components such as IGBT or SMD

- Quality assembly

- SMT

- Sensors

- Control modules

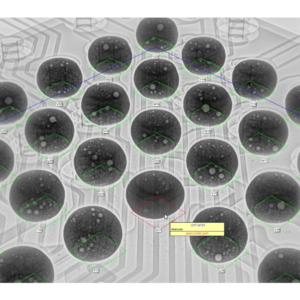

Brilliant DXR-HD live images

Waygate Technologies’ exclusive shiny fleet of DXR-HD detectors:

- Newest large DXR S100 Pro detector: superior pixel resolution that defines industry-leading imaging technology.

- Superior 100 um pixel resolution combines exceptional detectability with high efficiency

- Large 300 mm x 250 mm active area significantly expands the view and redefines inspection efficiency.

- Suitable for a wide range of X-ray energies and customer applications

- Unique high dynamic DXR250RT detector : enhanced scintillation technology introduces a new industry standard for efficient live inspection:

30 fps at full resolution offers low noise coupled with brilliant image quality that ensures fast and detailed live inspection - Active temperature stabilization for accurate and reliable inspection results

- Extremely fast data acquisition in 3D CT mode

High performance with high resolution: Diamond|window

- Compared to conventional beryllium objectives, the Diamond|window enables higher power at a smaller focal spot. This ensures high resolution even at high throughput.

- Up to 2 times faster CT data acquisition at the same level of image quality

- High throughput with high resolution

- Non-toxic objective

- Improved stability of the focal spot position in long-term measurements

- Longer lens lifetime due to less degradation at higher power density

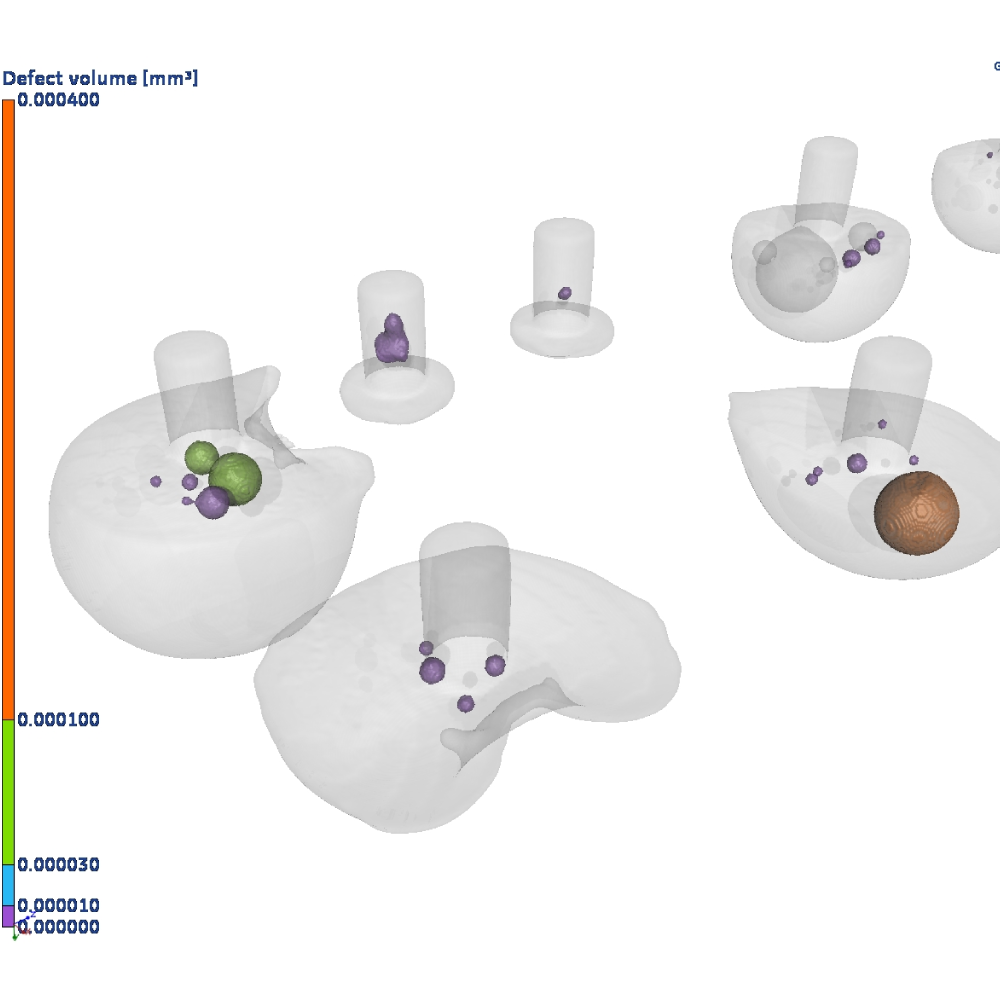

High-resolution 3D computed tomography

- For advanced inspection and 3D analysis of smaller samples, Phoenix|x-ray’s patented 3D CT technology is optionally available.

- Phoenix|x-ray’s patented 3D CT technology is available as an option.

- High-power 180 kV / 20 W X-ray technology, fast image acquisition with DXR detector and Diamond|window combined with Phoenix|x-ray’s fast reconstruction software deliver high quality inspection results.

- Maximum voxel resolution down to 2 microns; the nanoCT® capability of the Nanome|x allows for increased image sharpness.

- The mechanical precision of the CT rotation units is optimized for higher resolution CT applications.

X|act – CAD-based inspection: FLASH!

- For advanced inspection and 3D analysis of smaller samples, Phoenix|x-ray’s patented 3D CT technology is optionally available.

- High-power 180 kV / 20 W X-ray technology, fast image acquisition with DXR detector and Diamond|window combined with Phoenix|x-ray’s fast reconstruction software deliver high quality inspection results

- Maximum voxel resolution down to 2 microns; the nanoCT® capability of the Nanome|x allows for increased image sharpness.

- The mechanical precision of the CT rotation units is optimized for higher resolution CT applications.

Efficient CAD programming

High-resolution μAXI for extremely high defect coverage.

As a solution for μAXI with extremely high defect coverage, phoenix|x-ray provides its high-precision MicromeIx Neo and NanomeIx Neo systems including the unique X|act software package for fast and easy offline CAD programming.

Its new intuitive GUI with excellent accuracy and improved repeatability, small views with resolutions of only a few micrometers, 360° rotation and oblique viewing up to 70° ensures compliance with the highest quality standards, even for component inspection with a pitch of only 100 microns.

In addition to automated inspection, X|act ensures easy pad identification through its live CAD data overlay function even in manual inspection, while FLASH!™ image optimization guarantees high defect coverage.

Virtual panel cutting with Planar|CT

X|act provides not only minimal setup time compared to conventional view-based AXI: once programmed, the inspection program is portable to all X|act-compatible systems. The result is fast and easy programming: simply assign the inspection strategies and let X|act generate the automated inspection program.

Simple pad-based offline programming

Specific inspection strategies for different pad types

Fully automated generation of inspection programs

Extremely high positioning accuracy even in oblique view and rotation

Easy pad identification in manual X-ray inspection

High reproducibility on large PCBs

Virtual board cutting with Planar|CT

Planar|CT views of slices or multiple slices enable accurate inspection results of a single plane or a complete package.

Easy evaluation of 2D slices or 3D volumes of large and complex boards

No slab slices or structure overlaps as in X-ray imaging.

Newly designed workflow minimizes scan preparation and human interaction without loss of image quality.

Easy to use, less product knowledge is required to complete a flat CT inspection.

State-of-the-art detail detectability, speed and image quality

- Brilliant live inspection images with Waygate Technologies’ high dynamic DXR digital detector array

- Large 27″ monitor and ultra-high defect coverage and repeatability

- Detailed detectability at 0.5 µm or 0.2 µm with nano-focusing

- Live overlay of CAD and inspection results even in rotated oblique inspection views

- High power 180 kV / 20 W microfocus or nanofocus tube for high absorption electronic samples

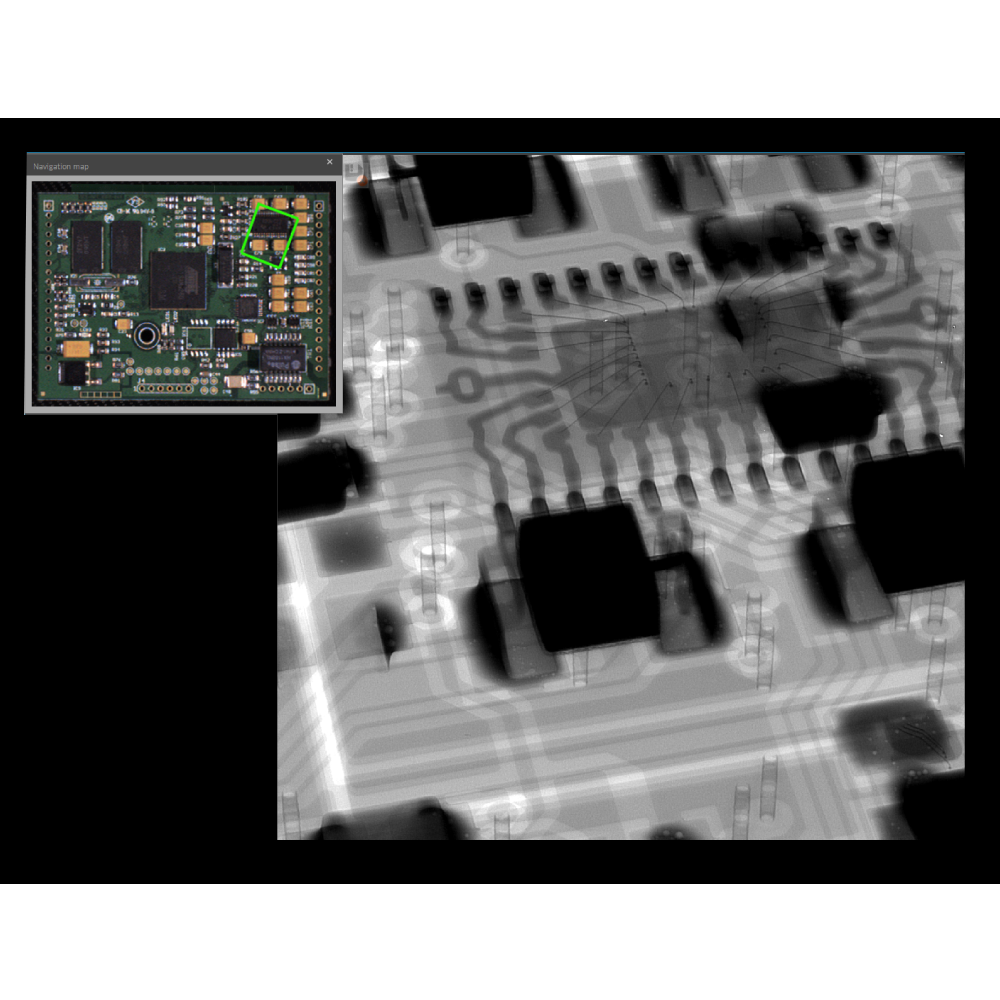

Navigation map orientation

Clear overview and fast positioning:

- Optical camera image or X-ray overview image of the complete specimen as navigation map.

- Quick manipulation by clicking on the map.

- The inspection program can be configured according to the optical navigation map.

- The position on the map can be saved in the test report generated by X|act.

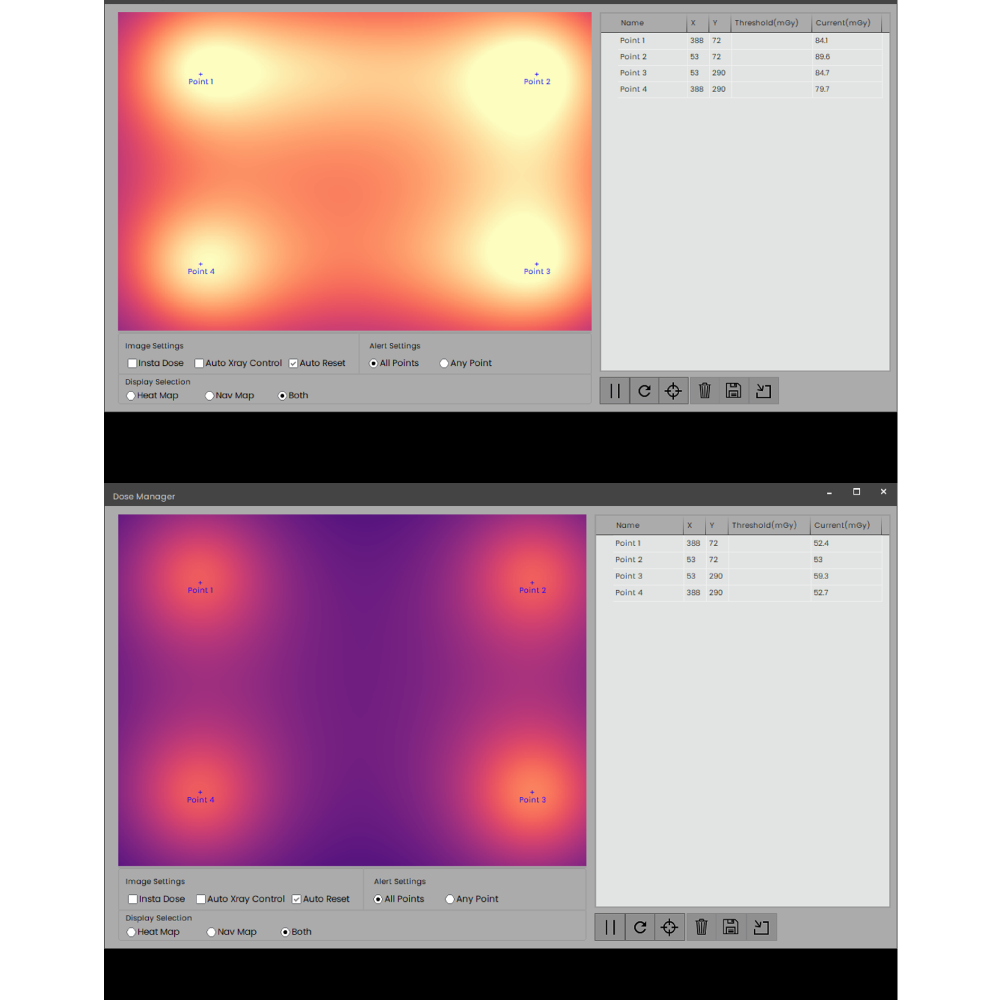

Intelligent dose management

Waygate Technologies’ patented Shadow|target inside the X-ray tube enables a reduction of unnecessary radiation dose by up to 60 % compared to conventional X-ray tubes during a typical inspection. Combined in a low dose package together with the new Dose|manager tool, it allows real-time dose monitoring and control.

This solution protects the inspected radiation-sensitive components from aging to the worst damage.

- Shadow|target avoids frequent start and stop of the generator to reduce unwanted radiation.

- Fast and stable X-ray recovery. No running power delay

- Real-time display of projected dose via the “dose map” overlaid with the navigation map

- Accumulated dose count per inspection

- Multi-position dose measurement well integrated into the inspection program

In the Dose|manager tool, rainbow coloring visualizes the projected X-ray dose in real time

Efficient and transportable for field applications

- Minimized setup time due to highly efficient automated CAD programming

- Designed for portability with compact, state-of-the-art electronics.

- Intuitive GUI interface with fully automated inspection program generation

3D scanning and optimization options

- Optional Flash!Electronics™ image processing technology

- Optional advanced flaw analysis with high-resolution 3D micro or nanoCT® or large-plate PlanarCT

- Optional 3D CT scans of up to 10 seconds

Reviews

There are no reviews yet.