Description

Ultrasonic phased array flaw detection starts here

The entire UT flaw detector system is housed in a glove-friendly touchscreen tablet that’s as easy to use as a smartphone. Pre-loaded Mentor Create software is fully customizable, allowing for user-defined menus and workflows (apps) for step-by-step guidance through the inspection process– from calibration to probe location to analysis. Confident and educated users mean that even the most complex inspections are performed consistently every time.

Mentor UT is the first ultrasonic testing device to easily allow wireless connectivity and live streaming, so inspectors can get real-time second opinions when they need them. That same wireless cloud connectivity enables Mentor UT to remotely generate comprehensive inspection reports on users’ desktops with the click of a button.

User-defined menus can walk technicians through every step of any inspection – from probe selection and calibration to reporting – ensuring consistency across your inspections, every time, from every inspector. And with the flexibility to load multiple workflows on one device, you can guarantee easy access to the right apps for any inspection.

Highlights

Benefits

- Conveniently upload & analyze your inspection data on your computer

- User-defined menus walk technicians through every step of any inspection

- Flexibility to load multiple workflows on one device

- Remote communication between experts and inspector

Features

- Remote calibration-capable

- High-performance design

- Rugged durability

- Intuitive operation

Applications

- Customize or create inspection “apps” for your unique testing procedures, industry applications, and experience levels

Mentor UT Features

High-performance design power efficiency

Mentor UT was designed around user needs. Its intuitive glove-friendly touch screen and a durability rating of IP65 allow for more accurate and efficient inspections, under any industrial conditions.

Perform inspections confidently using Mentor UT’s powerful 32:32 phased array flaw detector (upgradable to 32:128)with conventional UT channel and 18kHz pulse repetition frequency (PRF).

Perform starter end-to-end inspections with confidence

Ensure that UT inspections are performed consistently every time by custom-tailoring workflows (apps) to guide users through the calibration and inspection process step by step. On-board wireless connectivity and data export capabilities streamline one-touch reporting and analysis (offline analysis software included).

On-demand live support empowers inspectors to make on the spot maintenance decisions anywhere, anytime.

Unmatched versatility

Mentor UT also features unmatched probe versatility. Choose from commonly found Tyco or Ipex probe connection options, or industry-standard Phasor-style connector for improved probe compatibility.

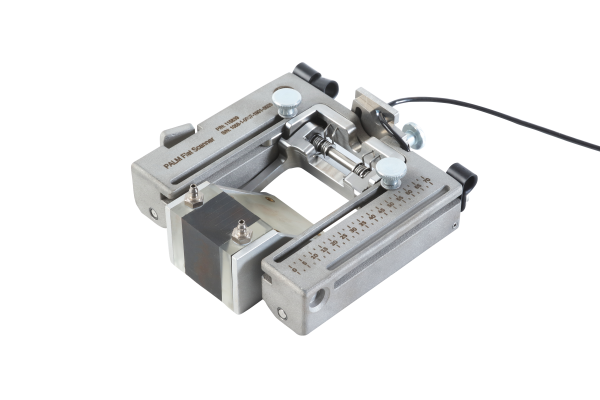

This device also easily pairs with Waygate Technologies’ industry-leading dual-element linear DM probes for corrosion inspection, linear array probes for weld testing and composite inspection, as well as a wide variety of commercially available scanners.

The preloaded Mentor Create software is fully customizable, allowing user-defined menus and workflows (applications) for step-by-step guidance through the inspection process, from calibration to probe placement and analysis. Confident and educated users mean that even the most complex inspections are performed consistently every time.

Mentor UT is the first ultrasonic test device to easily enable wireless connectivity and live streaming, so inspectors can get real-time second opinions when they need them.

That same wireless cloud connectivity allows Mentor UT to remotely generate full inspection reports on users’ desktops at the click of a button.

User-defined menus can guide technicians through every step of any inspection, from probe selection and calibration to reporting, ensuring consistency throughout their inspections, every time, from every inspector. And with the flexibility to load multiple workflows on one device, you can ensure easy access to the right applications for any inspection.

A process that used to be cumbersome and complicated has been simplified with the most comprehensive end-to-end ultrasonic testing solution available.

Reviews

There are no reviews yet.