Description

Spot weld inspection starts here.

Krautkrämer SpotVision from Waygate Technologies, developed in collaboration with automotive manufacturers, is the fastest, easiest and most accurate phased array solution for spot weld inspection. It provides confidence that parts are welded correctly. This increases productivity and ensures product safety and compliance with quality standards at all times

Highlights

- Increase process control

- Avoid false negatives

- Reduce training time

Features

- 2D phase matrix probe

- The membrane is liquid-filled, allowing it to accommodate irregular surfaces and the overall complex geometry of spot welds.

- With Total Focus Method (TFM) image processing, higher resolution and measurement accuracy is achieved with a comparable phased array.

Applications

- Automotive industry

Krautkrämer SpotVision features

An industry first

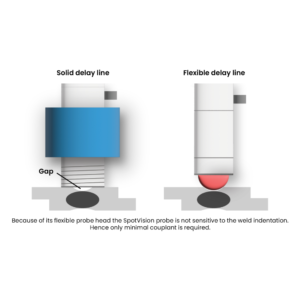

The solution combines a phased array probe and the Mentor UT phased array flaw detector to obtain complete information at the highest level. One of the most notable features of the newly developed 2D phased array probe is its flexible, liquid-filled delay line. This allows it to adapt to the overall complex geometry of spot welds. The flexible probe also provides optimal acoustic coupling, avoiding false negatives and minimizing process delays.

Better knowledge leads to better results

The 2D array probe is combined with the Total Focus Method (TFM) imaging technique. This achieves higher resolution and measurement accuracy than with a comparable phased array. Thanks to TFM, each element is triggered individually and sequentially while all elements are listening.

Reduced costs through increased confidence

Krautkrämer SpotVision is easy to set up and operate, reducing the need for training of qualified inspection personnel. This is due to the software’s intuitive user interface. In addition, the Mentor PC Live software connects the instrument to a PC via Ethernet, which is especially useful when the operator is in a different location.

Accessories

Starter Kit UP680023

- Mentor UT SpotVision Starter Kit (Mentor UT, including power adapter, Mentor remote battery, communication module, shipping case, probe connector adapter)

- Probe: G13MAPA-32 (SpotVision 2D phased array probe, 32 elements)

- Tyro 8-button remote control.

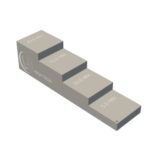

- SpotVision reference block (Reference block including 9 different machined nuggets, diameter ranging from ø2.5 to ø6.5 mm).

Krautkrämer SpotVision upgrade kit UP680024

- USB drive with SpotVision UT SW and Docs (USB drive containing the software installers for the SpotVision application and documentation).

Probe: G13MAPA-32 (SpotVision 2D phased array probe, 32 elements).

Tyro 8-button remote control.

SpotVision reference block (Reference block including 9 different machined nuggets, diameter ranging from ø2.5 to ø6.5 mm).

The Krautkrämer portfolio

Krautkrämer SpotVision is part of Waygate Technologies’ portfolio for joint inspection. This includes the Krautkrämer Bond Scanner for inspecting bonded joints with fast and easy-to-interpret 100% coverage. Both solutions are designed for ideal use in combination with the Krautkrämer Mentor UT phased array flaw detector.

Reviews

There are no reviews yet.