Description

Computed radiography starts here

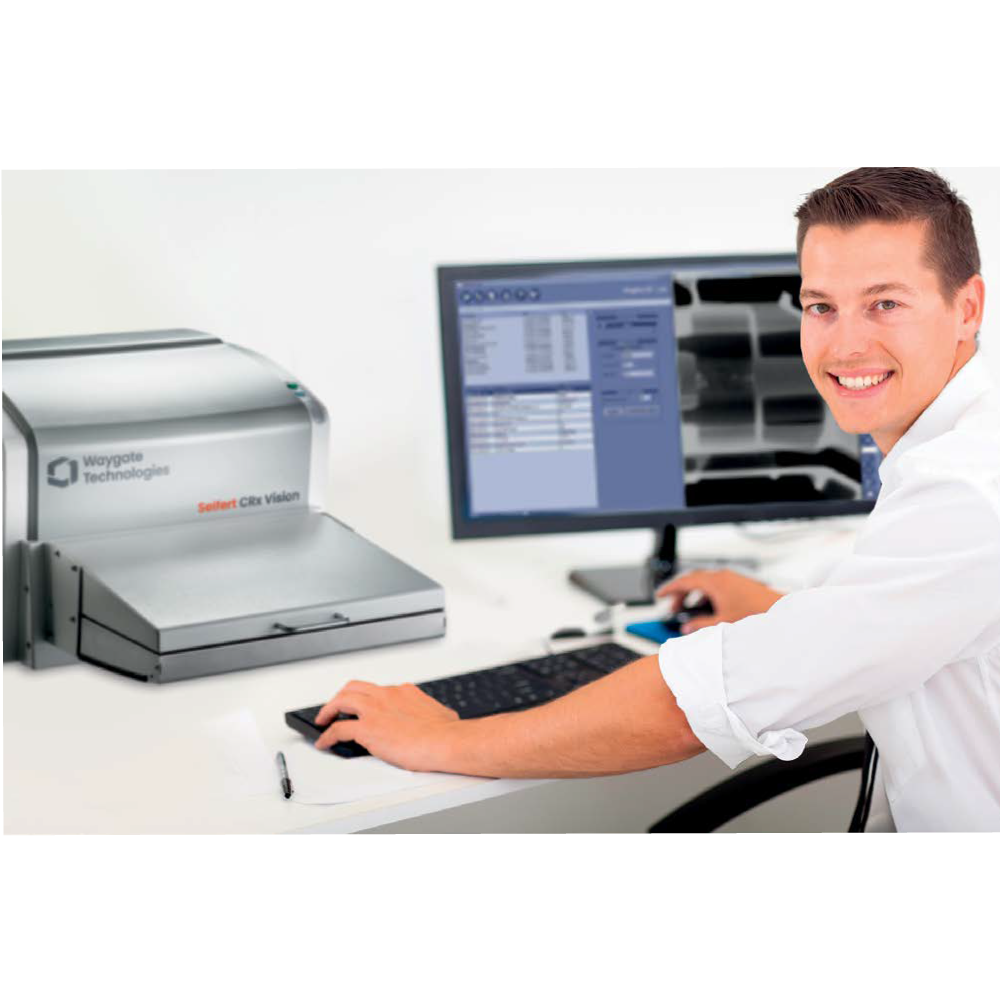

Equipped with innovative features to increase throughput, extend plate life and provide excellent image quality, the CRxVision is designed specifically for weld inspection. Due to its versatility, it can also be used for many other applications in the NDT industry.

An innovative new imaging plate design now provides more flexibility to CRxVision imaging plates. This new design allows each imaging plate the ability to return to a flat state after constantly bending around pipes for weld inspection. This feature also helps improve productivity by allowing imaging plates to be easily removed and reinserted into cassettes.

Benefits

- It complies with ISO 17636-2 Class A and B, ASME, ASTM and EN weld inspection standards.

- The CRxVision has an extremely wide latitude that eliminates the need for multiple gain settings.

- Weld exposure times are equal to or better than existing film exposure times.

- The scanner allows multiple imaging plates to be scanned simultaneously.

- Imaging plates can be exposed in any type of cassette, then simply removed and inserted directly into the scanner.

- A new innovative imaging plate design now gives CRxVision imaging plates more flexibility.

Features

CRxVision: the new versatile benchtop scanner

- Flexible and accepts a wide range of sizes, shapes and types of imaging plates.

- Intuitive with no gain settings or photomultiplier adjustments needed when exposing various thicknesses

- Fast multiple-plate scanning option: side-by-side and back-to-back with a flat transport path

- New high-resolution laser optics for deep reading and increased data extraction

- Extended plate life: no mechanical manipulation of the imaging plate during scanning and erasing.

- ASTM DICONDE compliant and fully compatible with Waygate Technologies’ existing Rhythm software platform.

- Environmental performance cover protects the imaging plate from light exposure.

- Direct laser contact: the laser beam is in direct contact with the imaging plate (no glass to obscure data collection).

Applications

Although CRxVision was designed for weld inspection, it also has the capability to cover a wide range of industrial radiography applications.

- Weld inspection

- Erosion/corrosion inspection (CUI, FAC, etc.)

- Castings (In-process and final)

- Valve positioning

- Concrete and structural inspection.

- Government (arsenals, national laboratories, proving grounds)

- Military (aircraft in service, ships, etc.)

Reviews

There are no reviews yet.