Description

This is where the fast, simple and accurate inspection of bonded joints begins.

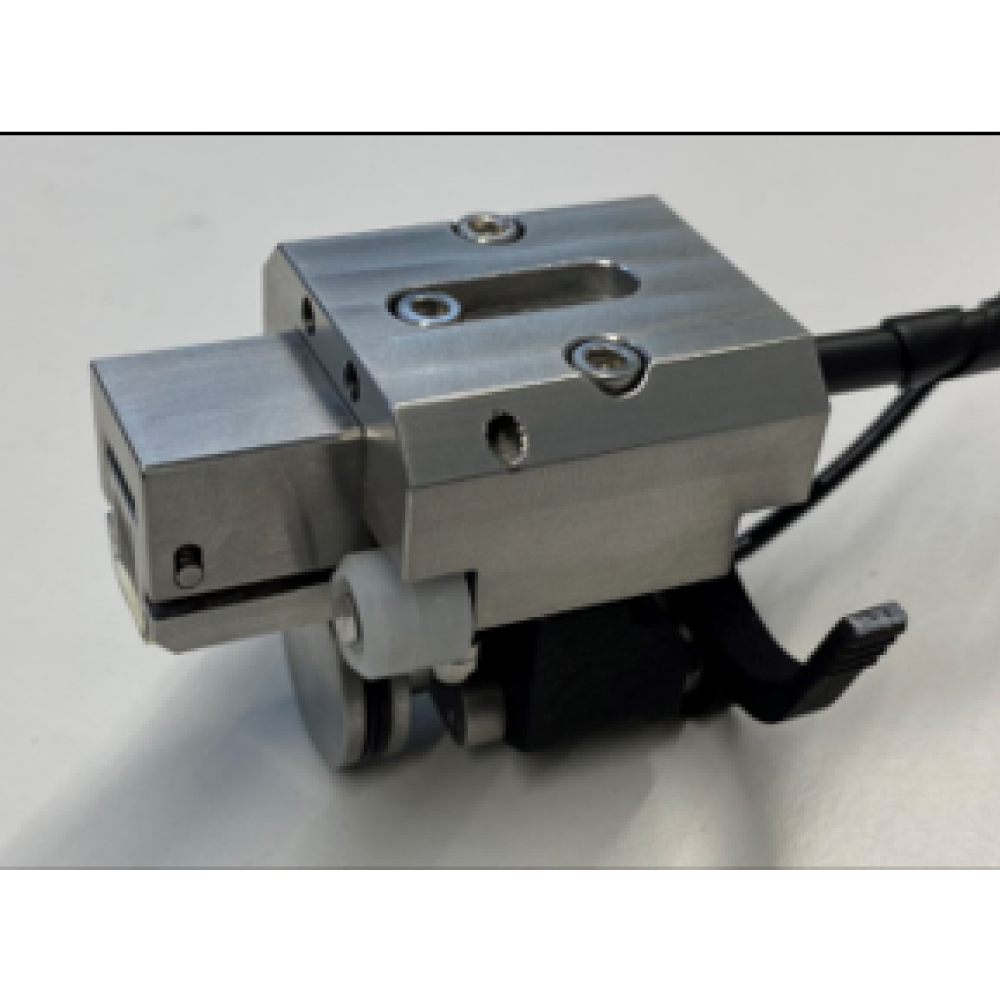

The Bond Scanner simply attaches to the two body panels joined by a seam bond. The innovative die design allows the die to also accommodate contoured parts such as those commonly used in automotive designs and covers bond lines up to 32 mm wide.

Since the spring-loaded encoder wheel is located on the other side of the plate combination, a firm and stable position of the assembly can be achieved. The specially designed protective foil reduces the required coupler to a minimum and allows one-handed manual scanning. Entire sections of body bonding joints (e.g. on hoods, doors or other assembled parts) can be inspected with a single scan. Knowing whether your parts are bonded properly increases productivity and ensures that product quality and safety standards are always met.

This solution allows the inspector to evaluate the full width of the bond joints and identify misaligned bond lines or areas lacking adhesive. The Bond Scanner can be used in all industrial sectors where bond lines need to be evaluated.

Highlights

- Fast results

- Accurate analysis

Features

- Flex Bond Scanner allows easy inspection of complex geometries that are increasingly found in modern automotive designs.

- The adjustable bond scanner examines many different bond bond geometries with a single probe.

Advanced Bond Scanner provides the detail that any higher quality standard would require with 64 elements and a 0.5 mm/20 mil pitch.

Applications

- Adhesives in the automotive and other industries.

Bond Scanner Portfolio – Flexible Bond Scanner

This innovative scanner makes it easy to inspect complex geometries that are increasingly found in modern automotive designs. The pre-bent convex die design of the LA-10 32-element flexible scanner can accommodate both concave and convex curvatures, with a radius of curvature of approximately 80 mm or 3.2″ and the ability to inspect the A-side edge joint. lines up to 32 mm or 1.3″ wide.

Advanced Bond Scanner

When even higher resolution is required, the Advanced Bond Scanner is the perfect solution. With 64 elements and a 0.5 mm/20 mil pitch, it provides the detail that any higher quality standard would require.

Adjustable Bond Scanner

This flexible scanner examines many different bond joint geometries with a single probe. It can be adapted to inspect adhesive joints with widths ranging from 8 to 20 mm or 0.315″ to 0.787″ from the A and B side edges. Note: Flat mating surfaces are necessary to ensure proper engagement of the probe to the surface near the edge being inspected.

Pair Bond Scanner with Mentor UT

For consistency throughout the inspection process, Bond scanners are ideally combined with the Krautkrämer Mentor UT flaw detector. User-defined workflows guide the inspector through every step of the instrument setup, from probe selection and calibration to report generation.

With Mentor PC Live software, the instrument connects to a PC via Wifi or Ethernet, which is especially useful when the operator is in a different location.

Mentor PC Live performs the instrument functions from the PC, with the advantage that configuration files and data are saved directly to the PC. Bond Scanner is also available separately.

.

Audiovisual resources

Reviews

There are no reviews yet.