Description

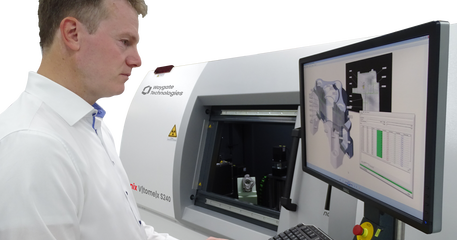

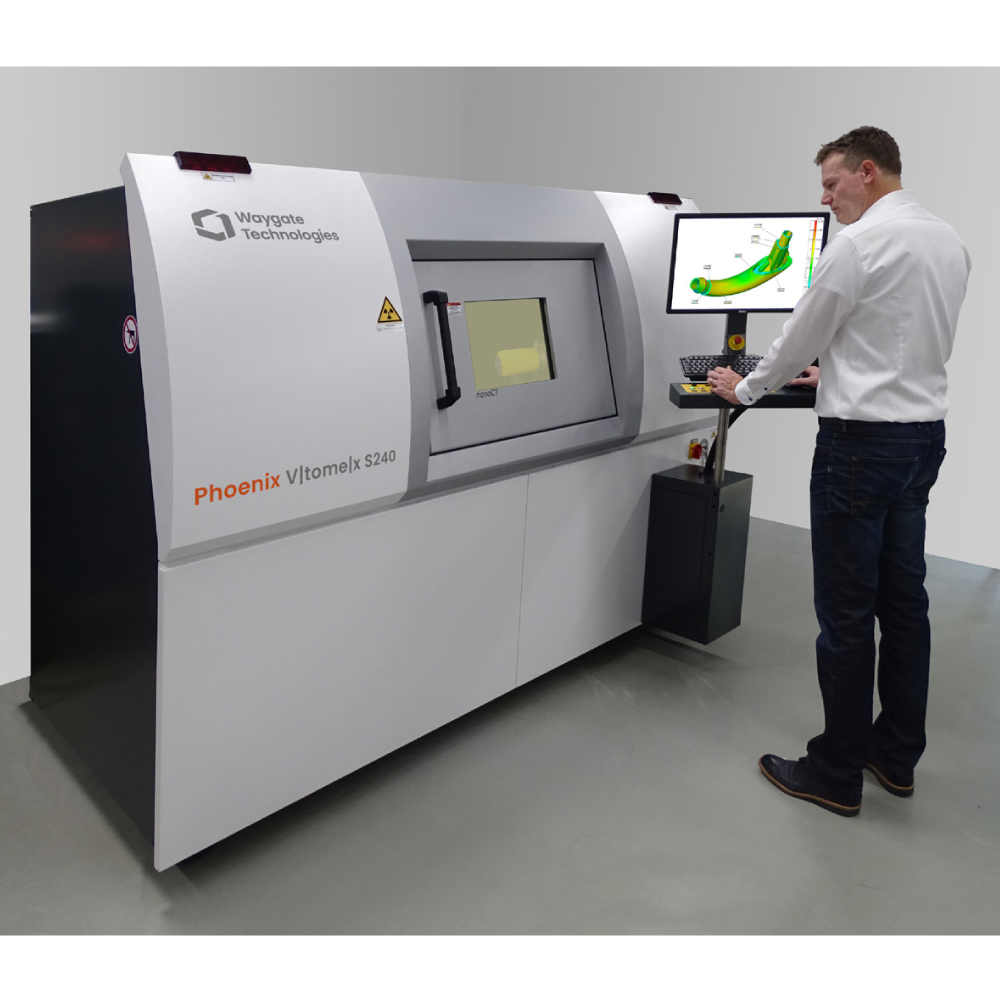

Whether you need to increase speed, detection detail, or both, the

Phoenix V|tome|x S240 from Waygate Technologies, a division of Baker Hughes, can be adapted to any scientific or industrial 3D microCT task. This CT scanner is ideally suited to meet the inspection challenges of industries such as electronics, R&D, scientific and automotive.

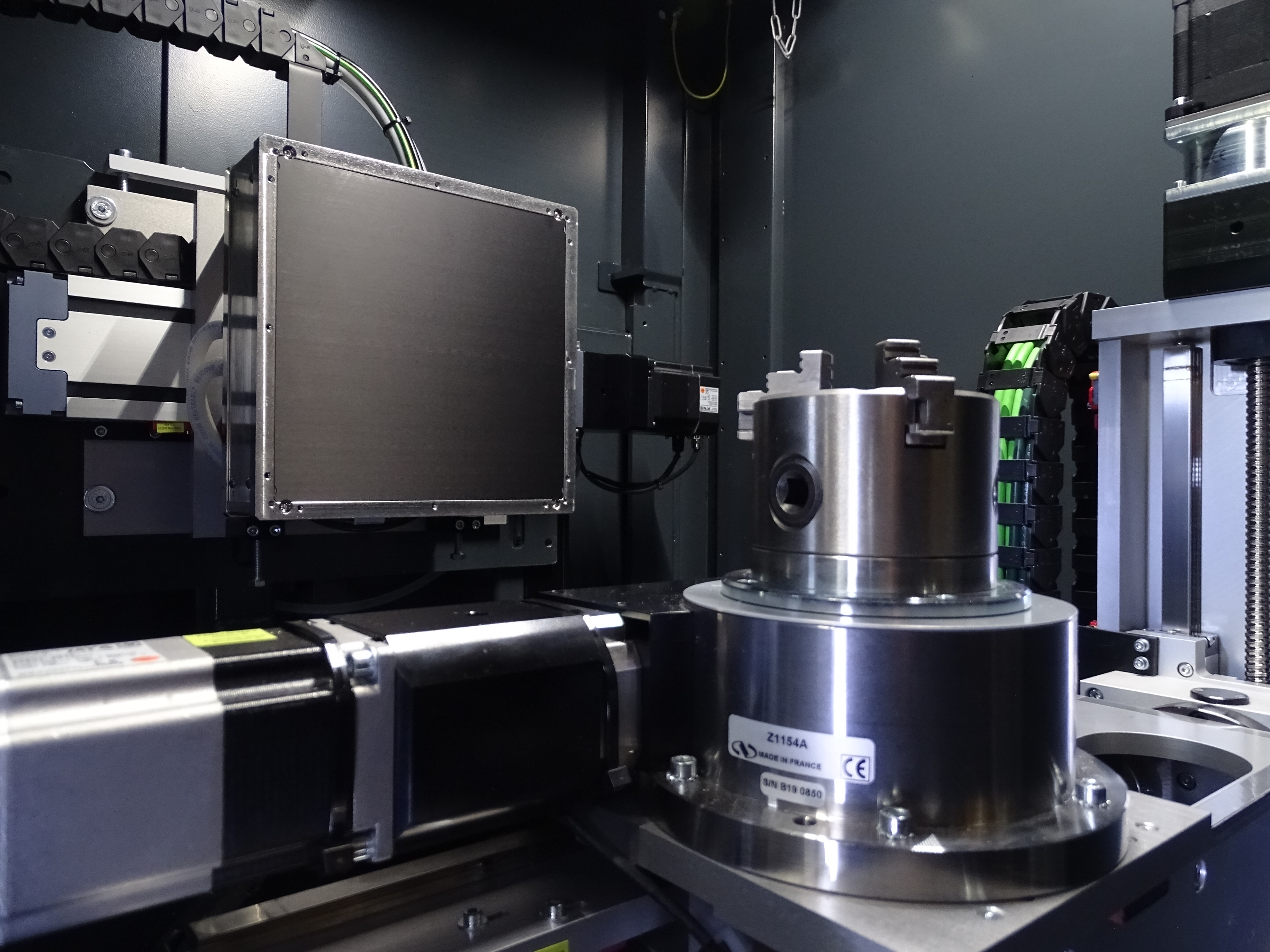

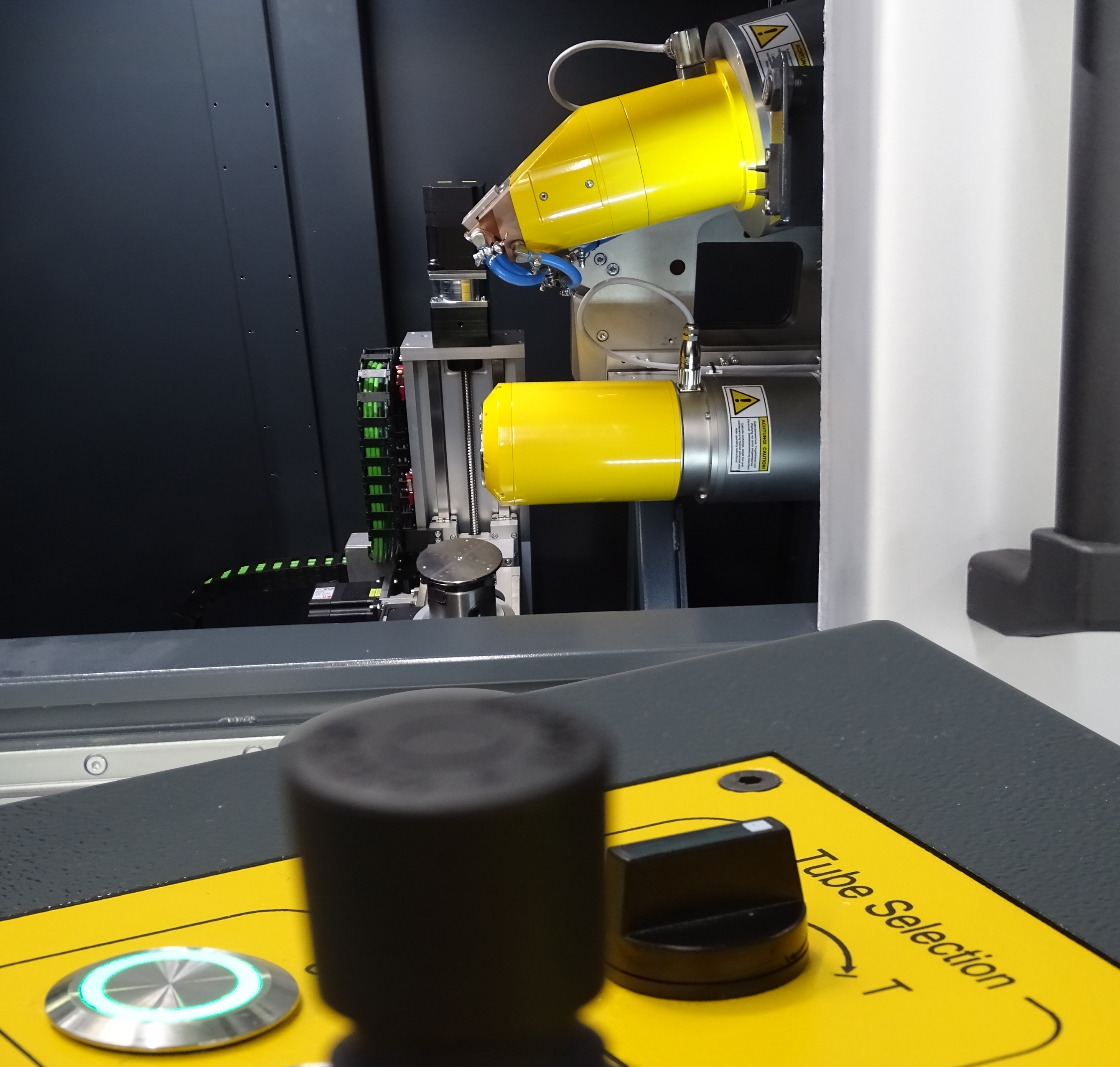

To offer high flexibility, the V|tome|x S240 scanner can be equipped with a 180 kV/20 W high-energy X-ray tube with nanofocus and a 240 kV/320 W X-ray tube with microfocus. Thanks to this unique combination, the system is an ideal tool for a wide range of applications: from nanoCT scans with extremely high resolution and the market’s best detection capability of 0.2 micrometers for materials with a low degree of absorption, to 3D analysis of objects with a higher degree of absorption and weighing up to 15 kg and 500 mm in diameter with microCT.

The best-selling industrial CT system, now better than ever.

When it was launched in 2003, the Phoenix V|tome|x S was the first high-resolution microCT and nanoCT® system for laboratories. With its unique Dual|tube configuration option, it quickly became the best-selling CT system in its class for research institutes and quality labs around the world.

With the next generation of this popular system now available, customers can enjoy enhanced features, coupled with the unprecedented versatility of the 2D and 3D CT inspection system, combining high resolution, ease of use and reliability with an excellent price/performance ratio.

Main advantages:

- Several possible configurations. Flexibility to use a dual open nanofocus-microfocus tube combination (high energy nanofocus X-ray tube with 180 kV/20 W and microfocus tube with 240 kV/320 W).

- Three different detector options depending on the inspection task, e.g. DXR S100 Pro with 2500 x 3000 pixels and a pixel size of 100 μm for superior resolution and exceptional detection capability

- Full reliability. Up to 10 times longer lifetime to ensure long-term stability and optimize system efficiency with long-life|filament

- Superior speed without sacrificing image quality. Up to 2 times faster acquisition at the same high image quality level thanks to diamond|window

- Maximized scanning flexibility with optional offset|scan and helix|scan features

- High performance with high quality of results: The Phoenix V|tome|x S240 is one of the few CT systems in the world to combine the highly efficient Dynamic 41 detector and High-flux|target technology, enabling high image quality with much higher scanning speed or higher accuracy.

- Full 2D inspection function: manipulator tilt axis (+/-45°) allows radiographic inspections with a high degree of flexibility

- Image optimization with Flash!: new generation with superior flaw detection capability, optimized for the inspection of 2D moldings and electronic components and 2D electronic components

Product Features-The best-selling CT System

With some 500 units sold, the Phoenix V|tome|x S is the dual-tube CT system with the largest install base in the world and offers unique flexibility that enables its use in applications ranging from 2D radiographic inspection to microCT and nanoCT. With the recent launch of the new generation V|tome|x S, the system is even better.

High performance image capture detectors

Choose the best detector option for your inspection needs:

- Dynamic 41|200p+ large area detector with temperature stabilizer offering superior image quality and results, 410 x 410 mm, 200 µm pixel size, 2036 x 2036 pixels (4 MP).

- DXR S100 Pro detector, 100 μm pixel size, 2500 x 3000 pixels for superior resolution and exceptional detection capability over a large active area of 300 mm x 250 mm, optionally with 1.3x virtual detector magnification

- DXR 250RT detector with temperature stabilization and 20 fps for real-time inspection, 200 μm pixel size, 1000 x 1000 pixels in a large 200 mm x 200 mm active area with 2x virtual detector magnification

Increased efficiency and reliable results

The patented High-flux|target component increases CT scanning efficiency, with CT scans up to twice as fast or twice the resolution. Review results faster than ever before thanks to velo|CT-accelerated 3D CT reconstruction and automated generation of first-article inspection reports that are available in one hour or less.

Wide inspection range

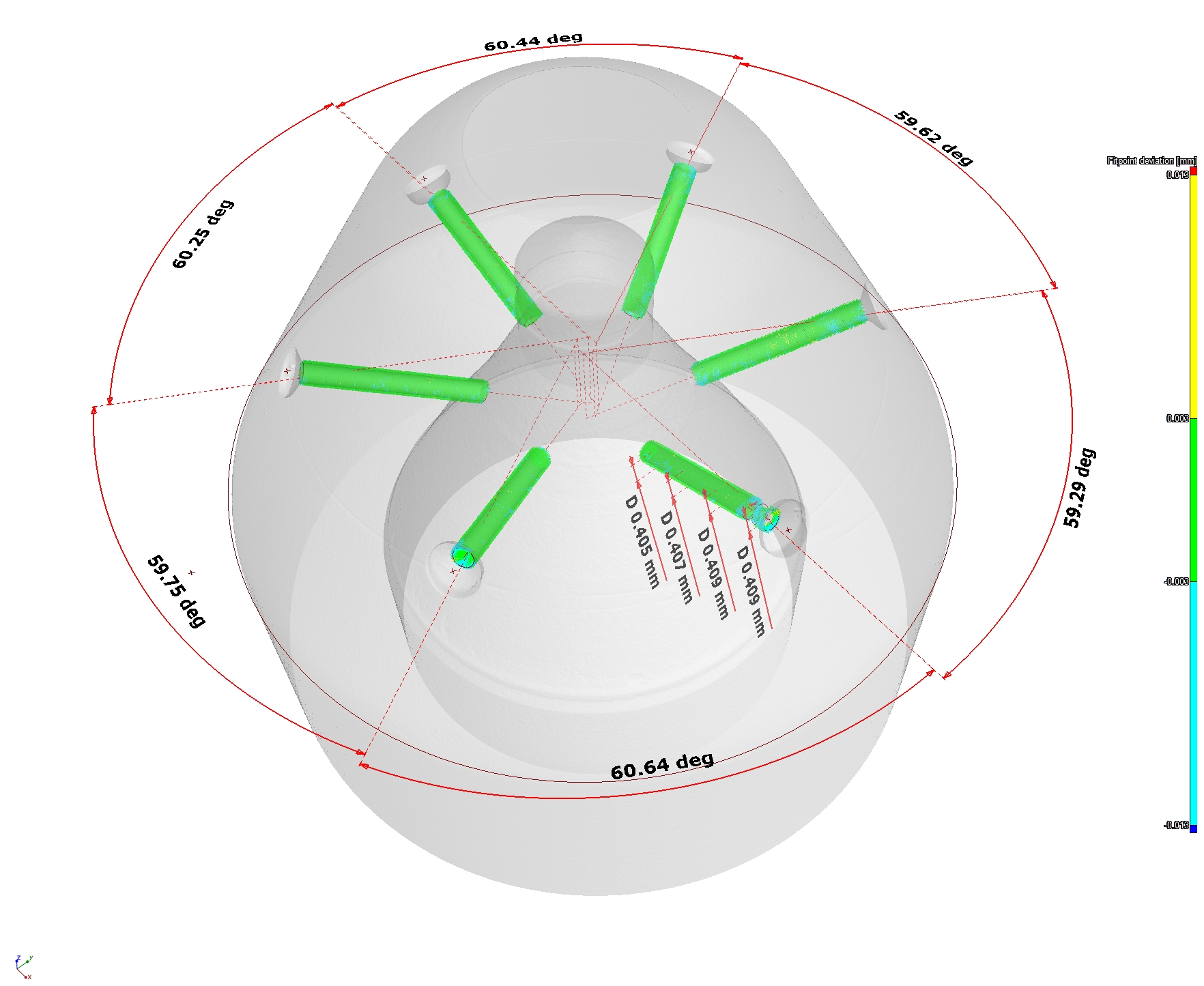

The 3D Measurement package delivers the most accurate and reliable results, while the simplified software and fully automated execution of CT scanning, reconstruction and analysis processes make capturing and reproducing high-quality inspection images easier than ever.

The 3D Measurement package delivers the most accurate and reliable results, while the simplified software and fully automated execution of CT scanning, reconstruction and analysis processes make capturing and reproducing high-quality inspection images easier than ever.

Extremely high accuracy and ease of use

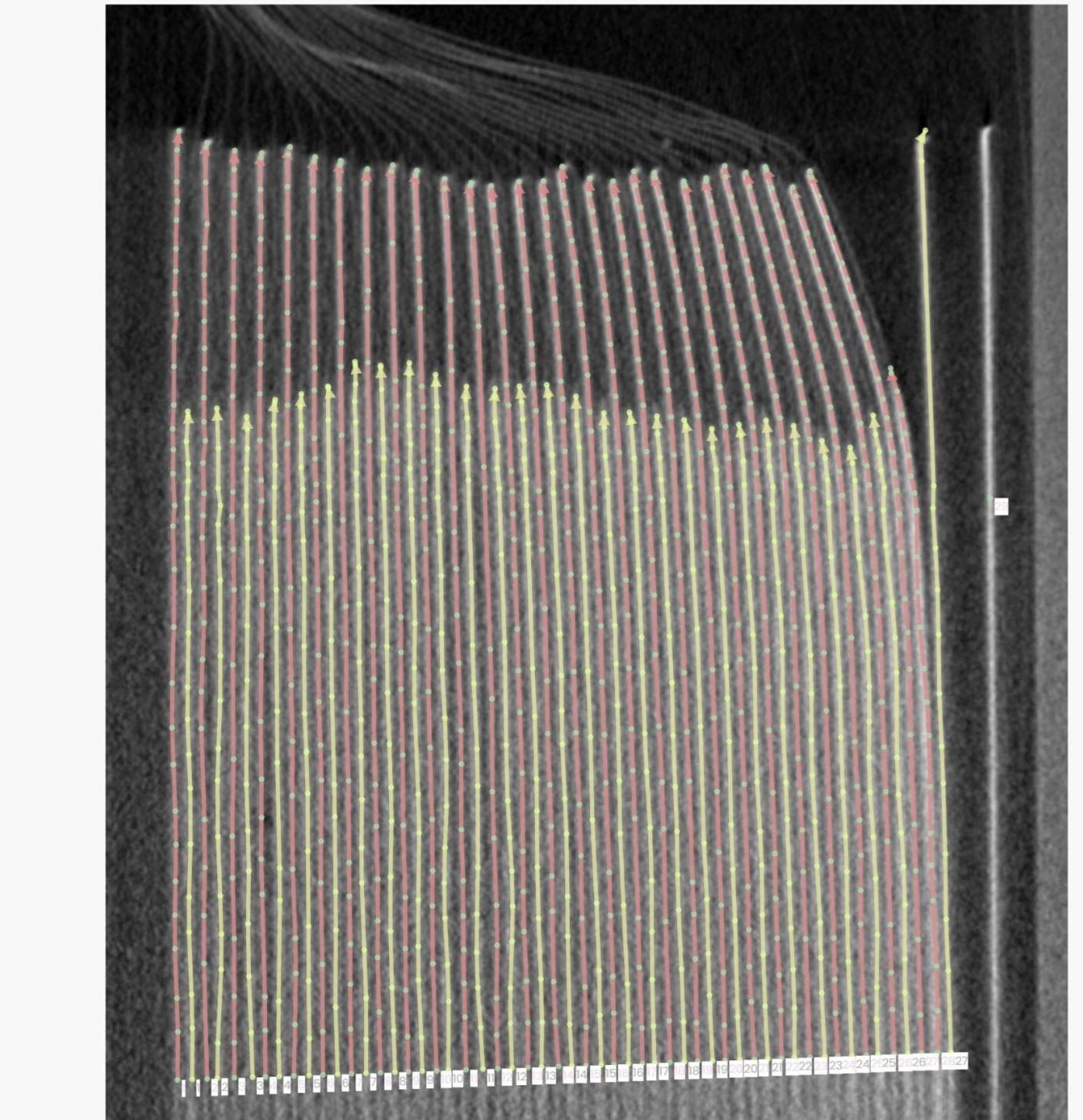

Proprietary artificial intelligence (AI)-based algorithms provide exceptional automated defect recognition (ADR) for various defects; for example, battery anode protrusion analysis or typical molding defects. Our AI-based ADR library provides superior accuracy and ease of use over conventional ADR methods, eliminating the need for specialized parameterization knowledge.

Waygate Technologies offers X|approver, the next-generation premium ADR platform, which features comprehensive and intuitive workflow management and a comprehensive ADR library that runs in the background during production to automate decision-making. In addition, reporting capabilities allow potential negative production trends to be spotted at a glance.

Any authorized operator can parameterize the scanned samples (e.g., for high-precision protrusion defect detection) and the algorithms improve their accuracy over time.

Flash-optimized 2D flaw detection

For advanced 2D inspection, the Phoenix V|tome|x S includes X|act inspection software with leading Flash!™ intelligent image processing technology to optimize flaw detection. Two versions are available to users:

- Flash! (for general NDT use, such as molding inspections).

- Flash! Electronics (optimized for electronic component inspection).

Reviews

There are no reviews yet.